How Do We Test For Continuity Using Digital Multimeters?

As far as testing is concerned, testing for continuity also holds a big deal to know if something is wrong with your electrical circuit. It takes a significant stand in testing since it will allow you to know if there’s something wrong with the current flow. Technically, it checks if the current in the circuit is still continuous.

Think of it this way, if a straw is bent, little liquid can pass through it and if in such circumstances that it is punctured, then all liquids will likely seep through that hole. It is the same thing with electrical circuits. Devices will not function properly if the current can’t flow freely.

Watch out for these two things…

There are two things that you need to watch out for when you test for continuity. Mainly, these are the resistance between the two points measured. Ideally, low resistance means that there is electrical continuity. Meanwhile, high resistance means that the circuit is open and therefore, the continuity is lacking.

The best device to measure is a digital multimeter.

Fluke Digital Multimeters are one of the most versatile tools that a maintenance person can have. Not only does it boast advanced functions, but its efficiency is well-spoken. This infamous tool has all the qualities that Fluke tools possess, but the most notable one will truly be keeping workers safe from possible electrical hazards that are inevitable to happen.

These are the most preferred tools for testing continuity since digital multimeters can be used to test switches, fuses, electrical connections, conductors, and other components. Its flexibility to test multiple assets in one makes them the most suitable tool for the job.

Benefits of Continuity Testing

According to Power Assembles, in order for electricity to flow, things need to stay connected. Ideally, there can’t be any breaks in the pathway or there won’t be a continuous flow of electricity. And this is where the need for continuity testing comes in. One of the huge benefits that continuity testing holds is its ability to determine faults within electrical circuits that can be harmful to man in the long run. But that’s not all, take a look at the other benefits that they hold…

Other benefits of continuity testing:

- Continuity testing can let you determine if a circuit is open, closed, or shorted.

- It lets you know if a fuse is good or blown.

- Makes sure a switch is operating properly.

- Verifies wires operating on the same circuit.

- Validates whether wire and cable assemblies are functional.

- Helps test the resistance of conductors.

Here’s a quick guide on how you can do continuity testing using digital multimeters.

Let’s go into detail on how you can safely perform a continuity test using your digital multimeter. And no, it’s not as complicated as you may think. It’s actually fairly easy to understand, it only takes a couple of steps for you to give this a shot. According to an official Fluke source, here’s how you can do it…

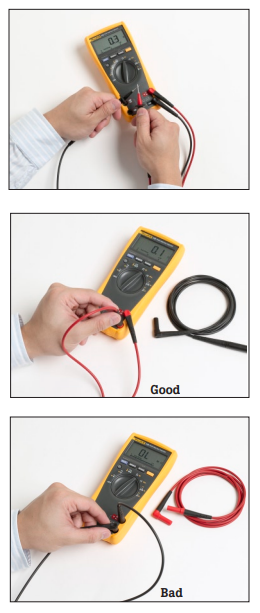

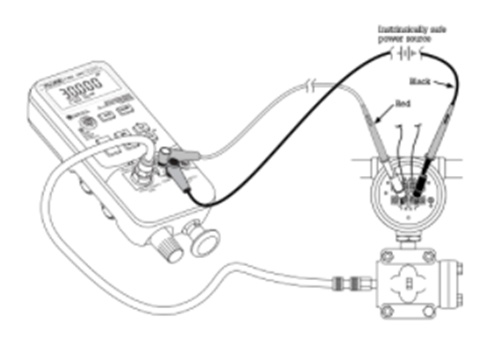

- First, insert the black test lead into the COM jack.

- Then insert the red lead into the VΩ jack. When finished, remove the leads in reverse order: red first, then black.

- With the circuit de-energized, connect the test leads across the component being tested. The position of the test leads is arbitrary. Note that the component may need to be isolated from other components in the circuit.

- The digital multimeter (DMM) beeps if a complete path (continuity) is detected. If the circuit is open (the switch is in the OFF position), the DMM will not beep.

- When finished, turn the multimeter OFF to preserve battery life.

Get your digital multimeters through an authentic source!

Hey, you made it to the bottom! Are you currently looking for the best-performing test tools in the market to run daily maintenance checks on your machines? You’re in luck cause Presidium PH is an authorized distributor of Fluke test tools in the Philippines. Prevent these faults from penetrating your machine by using the best test tools there are!

If you want to know more about Fluke tools and their functions, visit our website for more info! This is a one-stop shop for the best test tools within Metro Manila.

Shop Now: https://presidium.ph/?s=clamp+meter+