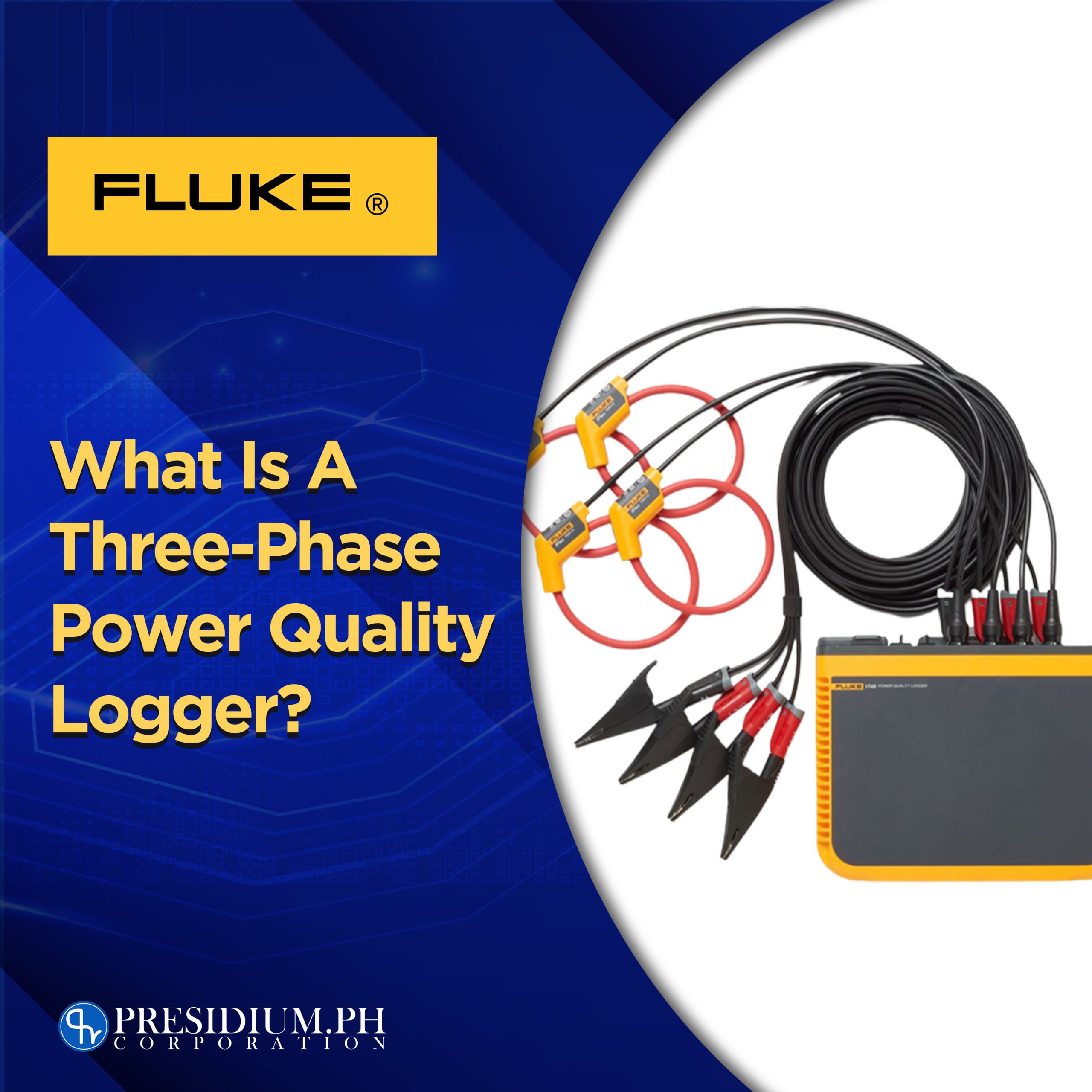

What Is a Three-Phase Power Quality Logger?

Reliable, quick, and easy, the Fluke three-phase quality logger can perform all the needed studies to ensure the logging of power quality in every machine is accurate and reliable. Like any Fluke tool, the power logger can perform under pressure, is accurate (considering that you do calibration), and can withstand any rough environments. Ideally, this three-phase power quality logger can be used in three different areas of testing.

- Electrical load studies

- Energy consumption testing

- General power quality logging

- They measure harmonics

- Electrical power parameters

- Capturing of voltage events

However, that’s only a gist of what they do. Here, we’ll be able to know more about how a three-phase quality logger can contribute to your electrical machines.

They come with a lot of phases.

They are generally known as power quality loggers, but they also come in the name of “energy loggers”. So don’t get confused when you hear both terms. Anyhow, you’re probably wondering how these things have “a lot of phases”. However, what we truly mean by this is that it comes with variations. Moreover, if you’re spotting a power quality logger, you can find that there is a one-phase logger, two-phase, and of course, a three-phase power logger. So, it’s probably wise for you to assess your machine and your test projects first before getting one.

Its notable applications…

Power quality loggers can be applied to different forms of testing. An authorized Fluke source pointed out its most beneficial functions when it comes to power quality logging. Here are some of them according to an official Fluke source.

- Load studies – Verify electrical system capacity before adding loads.

- Energy assessments – Quantify energy consumption before, and after improvements, to justify energy-saving devices.

- Harmonics measurements – Uncover harmonic issues that can damage or disrupt critical equipment.

- Voltage event capture – Monitor for dips and swells that cause spurious resets or nuisance circuit breaker tripping.

What does a three-phase quality logger do?

The thing about electrical power usage is that it is continuously and constantly changing. We may find wasted energy one day and wonder where it all came from. And this is the specialty of three-phase quality loggers. Ideally, the main priority of quality loggers is not only to detect the root cause of the problem but is also effective in doing all kinds of tests.

On the other hand, they can also do electrical load studies, energy consumption testing, and general power logging. Furthermore, with the use of Fluke’s three-phase power quality saving, you’ll be able to find out where and when you are consuming energy. A feature that is beneficial for you since you can know where you can adjust certain electrical practices, and this device gives you exactly that. As a result, you can now create credible power-saving strategies to avoid waste.

Finally, when you’re continuously logging energy usage, the three-phase quality logger can effectively assist you in quickly and easily identifying waste faults. Therefore, identifying saving opportunities can be all the easier for you.

The Fluke energy logger commands ease of use and quality performance.

A sweetener for every Fluke device is that it promises easy usability. Even a first-timer can be able to navigate his/her way through a Fluke device and it’s one of its winning qualities. But don’t be mistaken, this tool is more hardcore than you think. Here are more of them.

- Record power and associated parameters for up to 45 days.

- Monitor maximum power demand over user-defined averaging periods.

- Prove the benefit of efficiency improvements with energy consumption tests.

- Measure harmonic distortion caused by electronic loads.

- Improve reliability by capturing voltage dips and swells from load switching.

Resolve these failures using Fluke Tools!

Hey, you made it to the bottom! Are you currently looking for the best-performing test tools in the market to run daily maintenance checks on your machines? You’re in luck cause Presidium PH is an authorized distributor of Fluke test tools in the Philippines. Prevent these faults from penetrating your machine by using the best test tools there are!

If you want to know more about Fluke tools and their functions, visit our website for more info! This is a one-stop-shop for the best test tools within Metro Manila.

Shop now: https://presidium.ph/shop/?wlfilter=1&product_cat=fluke-power-quality-analyzers